Remove, replace and repair when necessary saving you time and money.

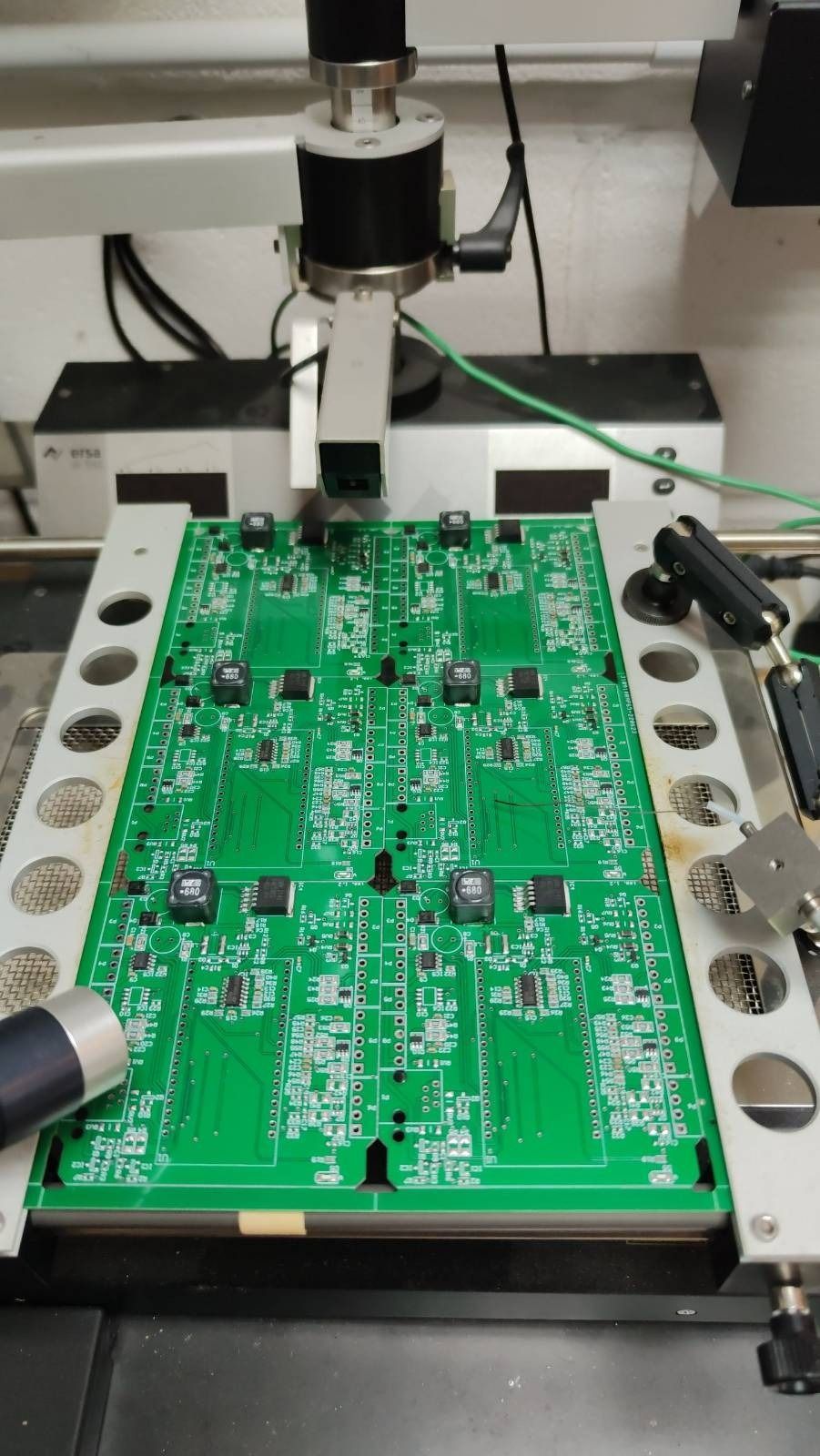

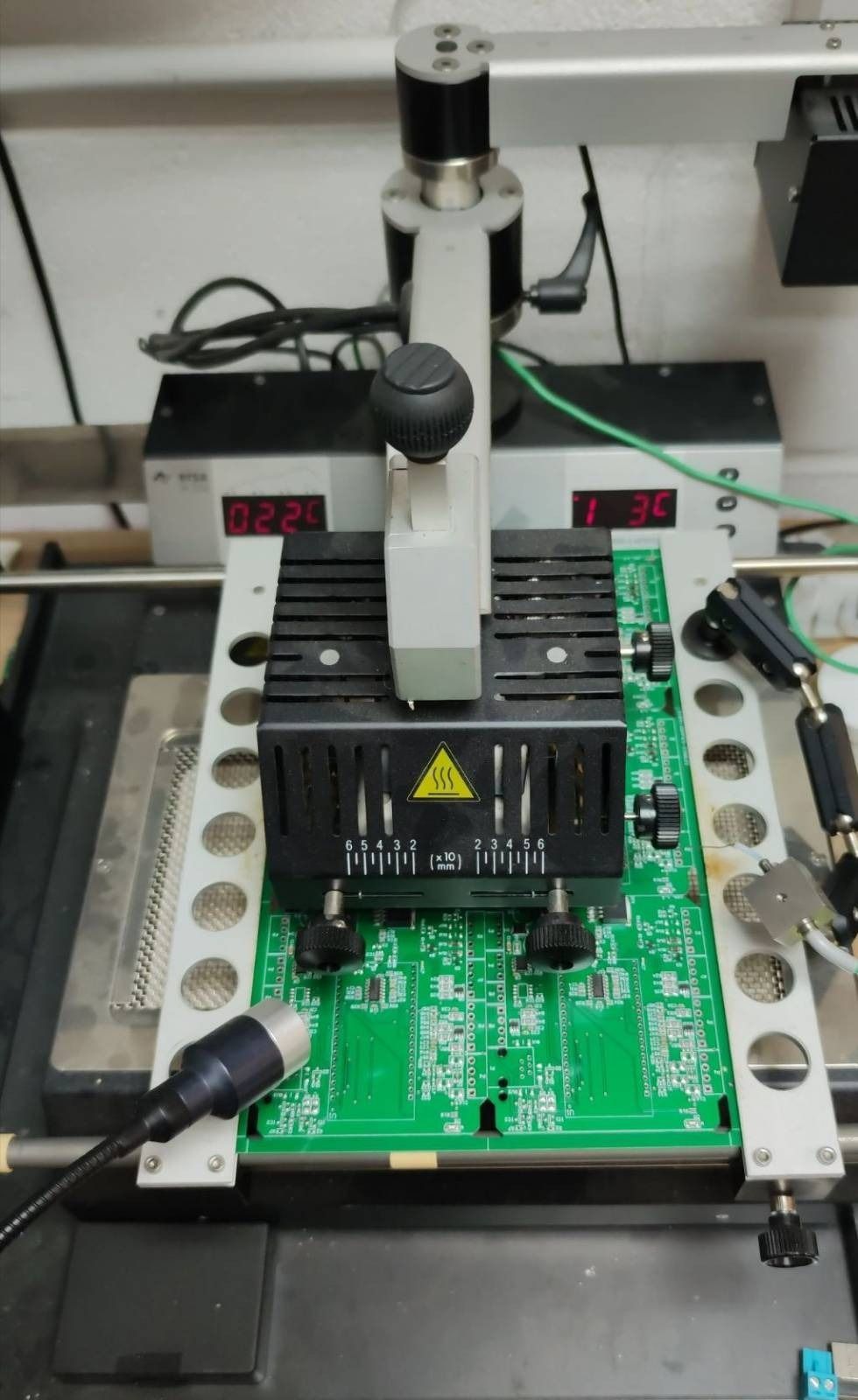

Device speed and capability is advancing at such a rate that some companies are finding it more cost effective to replace BGA's and other devices with new rather than rebuild the entire board. A re-work capability is also very handy should things go wrong and this is where our ERSA IR550 rework station comes into its own.

Non contact infrared sensing allows for precise board and component temperature monitoring for optimal control throughout the rework process.

ERSA Scope vision supports this rework enabling us to visualize BGA soldering results. The system enables us to measure the joints and to provide photographic images of the joints achieved.